Urethane square bars are manufactured from urethane and are commonly used in the machine handling industry for various applications. The urethane square bars that are custom manufactured by Plan Tech come in different sizes, standard durometer, and colors. The standard color popular during production comprises of red, natural or black; however, we also produce other colors based on the client specifications. We produce precision cast products daily and keep a large inventory in stock. Some common advantages of urethane square bars are: Standard urethane square bars are available Durometers available for urethane square bars range from 40A-95A All of our bar stock is precision cast producing even thicknesses and widths Inches and metric sizes available Custom shapes and sizes are available Good high-pressure seals The molds are cost effective to produce thousands of parts Urethane square bars can also be produced for other uses such as die cutting and bumpers which can be used for large industrial equipment. Plan Tech also produces urethane square bar stock that is utilized by shipping companies to protect delicate electrical equipment transit. We also add a variety of additives to enhance physical properties per the urethane square bar stock application, and our […]

Urethane Drain Plugs – Tight Tolerance Plugs!

Urethane drain plugs manufactured by Plan Tech are made from the very best urethane materials in the industry. We cast them in our fully equipped world-class in-house machine-shop using our sophisticated cast polyurethane facility. Our team of engineers who oversee the designing and manufacturing process takes every detail into consideration while ensuring that the flexible urethane drain plugs we produce are of top grade quality. Over the years flexible urethane drain plugs have become one of the industry standards and benchmark for quality as a means to easily and effectively seal different system components. During the production process, we cast the urethane into a mold to make the parts, and we machine the urethane in our in-house machine shop using our urethane technology and machinery to ensure that the flexible urethane drain plugs we produce are of unbeatable quality. As industry leaders, we have been manufacturing only the best in quality when it comes to flexible urethane drain plugs, and we achieve this using speed and precision. With our team of skilled engineers who have the technical prowess to manufacture wear resistant urethane drain plugs that meet the demand of any application, you can depend on us to […]

Polyurethane Forming Plugs – Wear Resistant Plugs!

Polyurethane forming plugs are one of the numerous polyurethane parts that we manufacture in our in-house machine shop. Plan Tech has been in the forefront of the Polyurethane industry since its establishment over 30 years ago. In this time we have become one of the predominant manufacturers in the United States of a wide range of products which include the polyurethane forming plugs. Our team of engineers is skilled with professional experience and technology to manufacture polyurethane forming plugs that are of international standards. They can help you design new forming plugs, revise an existing one, or even design a polyurethane forming plugs to replace an existing part that was previously made from metal or other types of plastic or rubber. Our polyurethane forming plugs seals and prevents spills from entering drains. They are also ideal for blocking drains before a spill or as soon as they occur. So whether you need urethane forming plugs for preventive maintenance or in an emergency to contain an unexpected spill, our polyurethane plugs are one of the best products that can help you protect your drains from hazardous materials. Tight Tolerance Polyurethane Forming Plugs Our polyurethane forming plugs are also […]

Polyurethane Check Valves – Wear Resistant Valves!

Polyurethane check valves are one of the high precision polyurethane products we manufacture in our fully equipped in-house machine shop using our state of art facilities. We manufacture polyurethane check valves using the best polyurethane materials in the industry. Also, our team of highly skilled engineers are well vast in the art of creating polyurethane check valves that are of world-class quality. Polyurethane check valves are used in pumps to improve pump performance. They also help pumps operate quietly and efficiently which makes polyurethane check valves the best option for check valves. Although polyurethane check valves are simple devices, they serve an important purpose in many pneumatic-control circuits or equipment. Generally used in systems with limited or no backflow, urethane check valves allow free flow in one direction and in most cases block flow in the opposite direction. They can also be used as a bypass valve, allowing media around other components in the system. Our poly check valves offer maximum resistance to abrasion, cutting, fatigue, corrosion, and chemicals, yielding superior performance and long service life in extremely harsh environments. Manufactured in a variety of diameters and durometers, our team of engineers can meet even the most stringent […]

Polyurethane Plates – Impact Resistant Urethane Plates!

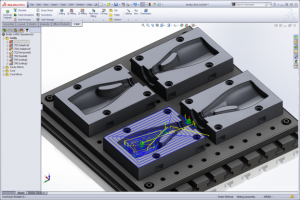

Polyurethane plates from Plan Tech continue to dominate the demanding industrial market today. This is due to the fact that they are made of superior quality and also perform better in a wide range of temperatures. Our in-house precision engineering team offers the capability to design and manufacture unique polyurethane plates to meet the requirements of our customers. Our team of technicians who develop these polyurethane plates uses advanced technology such as SolidWorks and AutoCAD as well as state of the art facilities found in our in-house machine shop. Following the requirements of our clients, they manufacture polyurethane plates with international quality standards. Having access to these facilities, they can create custom plates; this means they can easily make and shape them to fit any application, from light to medium or heavy duty. Our polyurethane plates are quick and safe to install, have good wear, tear, chemical and abrasion resistance as well as having low friction properties which makes it one of the best options for wet applications. They also provide better protection and eliminate odors compared to rubber coated plates. Plan Tech’s urethane plates do not leave residues that can mark floors and surfaces of other equipment like […]

FDA Compliant Urethane Wheels – Made In USA!

FDA compliant urethane wheels are replacing rubber, plastic and metal wheels at a rapid pace. At Plan Tech we understand that it is imperative that our products, materials, and equipment are FDA Dry Approved. As such our customers are specifying FDA compliant urethane wheels that are of premium grade materials, close tolerances, and custom formulations. Whether you need FDA compliant urethane wheels with industrial or food grade applications our FDA Dry compliant formulations and our team of engineers will help you achieve your custom formulation. Our technicians will also assist you from inception to completion of your project. They can help you determine the right load-bearing capacity depending on your desired application; they can also help with the core design of your fda compliant urethane wheels, the strength needed and the polyurethane compound that best suits your application. We use FDA compliant antimicrobial additives in our FDA compliant urethane wheels; this antimicrobial additive is used to suppress the growth of several destructive and odor-causing microbes including bacteria, mildew, molds, and fungi. FDA Compliant Urethane Wheels The breadth of the facilities in our in-house machine shop gives us the ability to customize any FDA compliant urethane […]

Robotics Industry Utilizing Urethane Molded Parts

Urethane offers excellent wear characteristics as well as resistance to chemicals, abrasion, and corrosion which has rendered it an asset to the robotics manufacturing industry. The robotics industry utilizing urethane parts take advantage of its extreme vibration dampening ability, it’s ability to navigate through smoothly even on uneven surfaces and operate well in extreme environments with heat, water, solvents, and chemicals. Robotics industry utilizing urethane parts attests to its superiority to other materials such as plastic and rubber. Due to its versatility and the wide range of engineering properties, urethane has been used to solve many problems from vibration to isolation, shock absorption, electrical isolation, and abrasion resistance. Also at Plan Tech, we create custom urethane parts with very low tooling costs for the robotics and other industries. All of our urethane components are custom designed and built to exacting client requirements. Each project begins with rapidly built prototypes manufactured at a low cost for testing and evaluation. So, whether you have a new design in mind or you just want to replace an existing one, Plan Tech is equipped with both the facility to help achieve your desires, and we also have the manpower or know-how to […]

Urethane Anvil Covers – Molded Anvil Covers!

Urethane anvil covers designed and manufactured by Plan Tech are undoubtedly one of the best urethane covers in the corrugated industry. Our in-house precision engineering unit offers the capability to design and manufacture world-class urethane anvil covers to meet the specification of our customers. Our urethane materials and proprietary urethane machine processing produce urethane anvil covers specifically designed for the demanding applications of the Corrugated Industry to save both time and money while providing better quality products. Plan Tech offers a complete line of urethane anvil covers designed for superior convenience and performance. This makes our urethane anvil covers ideal for virtually all applications. Using advanced technology in our fully-equipped in-house machine shop our team of technicians are able to produce urethane anvil covers that are tough, easy to install and has a precise streamline rotation. All these and its durable construction make it a preferred choice of corrugators around the world. Our urethane anvil covers do not just promise to enhance your productivity and profits, it is also abrasion resistant and features a rotation regimen that is easy to maintain. We provide multiple mounting versions; we also design and manufacture several different sizes in order to […]

Cast Polyurethane Diaphragms – Made In USA!

Cast polyurethane diaphragms manufactured by Plan Tech are used in numerous industries worldwide. We produce cast polyurethane diaphragms for both high and low-volume production. All the design features we’ve engineered into our diaphragms are intended to improve performance in a variety of applications. Created using high-performance resins, curatives, and additives, our cast polyurethane diaphragms can be designed and manufactured in almost any shape or hardness. Our in-house precision engineering unit makes this possible through a number of manufacturing processes which utilizes our state-of-the-art technology at each processing stage. All our polyurethane diaphragms are produced to match the exact original equipment, client’s requirement or manufacturers’ specifications guaranteeing precise fit and performance from every cast polyurethane diaphragms we produce. Also, our cast polyurethane diaphragms are wear and generally cut resistant, withstand harsh environments, possess amazing resilience, has an outstanding performance and can outlast other materials. We can supply diaphragm samples in a number of hardnesses for testing and evaluation. And to ease production from start to finish, cast polyurethane diaphragms are designed in-house, and rapid prototyping is made available. Our customers also have the flexibility of bringing their designs and having their parts cast to size or machine finished. Whether you are […]

Urethane Pipe Linings – Abrasion Resistant Linings!

Urethane pipe linings provide an effective solution to overcome corrosion and abrasion problems associated with moving material in during the production and construction process in industries. At Plan Tech, we fabricate and line a large range of urethane pipe linings and associated fittings including straight pipe, elbows, reducers tee spools, T-pieces, Y-pieces and much more. Our pipe spinning machines allow us to line pipe up to 12 meters in length. We make use of different methods of pipelining, depending on the shape of the pipe. Straight pipes are lined using the spinning process, while bends, Y-pieces, T-pieces and other complex shapes are lined by means of a disposable inner process. Now, due to our spinning process, the urethane pipe linings have a seamless finish with no joints or uneven surfaces. We are also able to provide extensive customizations for any urethane pipe linings application. Even if you have special requirements or specifications that cannot be met with an off-the-shelf product, you can get in touch with us. Our team of skilled engineers will listen to your need and fabricate your desired product. Our in-house capabilities will also help in reducing the production cycle time from receipt of order […]

Urethane Lined Fittings – Molded Urethane Fittings!

Urethane lined fittings are recognized as the ideal solutions for conveying or processing fluids under severe conditions. Plan Tech has been a long time provider of urethane lined fittings for clients throughout the United States and the world at large. For more than 30 years, we have been striving to provide our customers the best urethane lined fittings on the market today and to back that up with exceptional customer service and support. If you’re in the market for urethane lined fittings, we can help. We have an extensive supply of urethane lined fittings, and we are able to process and deliver orders for clients across the country quickly. We also offer extensive customization and fabrication services for special urethane lined fitting projects. Our urethane lined fittings are manufactured from concept to actual production with high dimensional accuracy and with the highest quality at our in-house facility. Urethane lined fittings are currently the most economical types of pipe fittings on the market. It offers a number of benefits, from good resistance to both basic and acidic chemicals to its resistance to corrosion, its high resilience and tear strength. Also, polyurethane lined fittings can be used safely in high […]

Solid Polyurethane Wheels – Wear Resistant Wheels!

Solid polyurethane wheels have proven to be the authentic solution for several industrial applications; they can be used for heavy wash-down and food grade environments. They are also steam cleanable and ideal for use in both food and pharmaceutical applications. Solid polyurethane wheel manufactured by Plan Tech provides a one-piece molded solution which eliminates the issues of tread bond failures often encountered when utilizing other materials. As a market leader in developing 21st-century polyurethane materials, Plan Tech makes use of the very best in-house technology and facilities to produce its solid polyurethane wheels. Made from high tech polymers and formulation, the Plan Tech engineering team can manufacture your solid polyurethane wheels in any shape, size, hardness and to any color you choose or that suits your application, whether in small or large batches. So, if you are looking for solid polyurethane wheels or replacements for your machinery, then you are in the right place. Our solid polyurethane wheels are manufactured with the expectation of a high performance, reliability, and a formulation that will withstand rigorous work environments. Our solid polyurethane wheels provide durability with resistance to chemicals, corrosion, solvents, heat, and abrasion which meets and exceeds several industrial […]

Urethane Hopper Linings – Abrasion Resistant Linings!

Urethane hopper linings manufactured by Plan Tech can bring new life to your operation process. Urethane hopper linings are put in place to protect equipment from prolonged wear, and the urethane formulation created by Plan Tech offers the best abrasion resistance the industry has to offer. The fact that urethane is chemical resistant and can be bonded to other materials like metal makes it the material of choice. Urethane hopper linings have proven to be great for the transportation or movement of sticky materials as the dirt or sludge rolls off easily. Urethane hopper linings are usually used to protect metal hoppers and chutes from abrasive and corrosive compounds, they are especially beneficial when used inside concrete mixers and hoppers. The superior performance of our urethane hopper lining in such viscous situations makes sustained use, cleanup, and care easy. Plan Tech is leading the way in the development of innovative urethane hopper linings. Our new technology can be used to design and fabricate one-piece, drop-in, industrial urethane hopper linings with complex designs. It is no news that our urethane hopper linings are preferred in many applications. They help minimize impact and sliding abrasion damage in abrasive situations, they […]

Urethane Lined Pipes – Wear Resistant Polyurethane!

Urethane lined pipes manufactured by Plan Tech are available in a large range of sizes, they can also be designed, fabricated and lined to any thickness depending on the requirements of the application. Whether you need a new build or a re-line, our highly talented craftsmen use the same rigorous process to provide you with the best quality urethane lined pipes the industry has to offer. From the design and fabrication to surface preparation of your urethane lined pipes, your specifications and requirement will be utilized. In the end, our engineers will deliver industrial-grade lined pipes that will be able to withstand chemical, abrasive, and corrosive slurries in suction or discharge service. The lining is typically created in our premium polyurethane formulation. Also, the pipe is molded or spun to the proper ID, then it is through-cured in our temperature controlled ovens to ensure complete cure. With this process, our urethane lined pipes are equipped to provide a superior method of moving viscous fluids and particulates. They are not just highly abrasion resistant pipes, but they can also outlast and are easier to replace than any other material on the market. Their tremendous wear life reduces maintenance and […]

Upstop Urethane Wheels – Tight Tolerances!

Upstop urethane wheels are one of the best bets for a safety mechanism to make sure trains are physically locked onto their track. Plan Tech’s upstop urethane wheels have been considered the perfect upstop wheel for high-speed roller coaster experience; this is because it offers low rolling resistance, smooth ride performance, high load endurance and high durability or low maintenance cost. For over 30 years Plan Tech has been supplying the Amusement Industry with high-quality upstop urethane wheels and products. Plan Tech offers a complete line of products that fit the demanding dynamics of the roller coaster industry. Plan Tech’s quality goes into each and every part as it continues to provide safe and reliable upstop urethane wheels. Our proprietary polyurethane formula allows our upstop urethane wheels to be one of the most durable available. They are designed to exhibit very good mechanical properties, and as such, they have very high resistance to weathering, as well as gas or oil. Our in-house capabilities also help in reducing production cycle time from receipt of order to the final delivery, and we use advanced technologies in our machine shop to ensure that your upstop urethane wheels meet all critical dimensions. […]

Molded Polyurethane Wear Strips – Abrasion Resistant!

Molded polyurethane wear strips are generally manufactured from highly durable polyurethane formulation that holds up to the toughest environments. Our molded polyurethane wear strips provide a high wear resistance and a low coefficient of friction during application. Our molded polyurethane wear strips are cast and molded with ultra-tough materials and have proven to cut downtime, maintenance time and cost of parts. In our business, quality is critical. We’ve built a three-decade reputation for reliability, precision, and service, and our dedicated team of engineers has made Plan Tech an industry leader in the production of molded polyurethane wear strips. Our molded polyurethane wear strips offer long run durability and extreme resistance to harsh environments of heat, water, solvents, chemicals, and abrasion. We can help you select the perfect molded polyurethane wear strips for your application. Custom needs? We can help with designing, molding, engineering, prototyping, and testing. We also offer a wide range of standard extruded profiles as well as machined profiles. We can produce custom-tailored profiles to suit your exact requirements. When it comes to molded polyurethane wear strips our massive inventory, quality control, and unparalleled customer service are the secrets to our success in the industry. Below […]

Urethane Compression Molding – 50-Ton Molding Presses!

Urethane Compression Molding ? You’ve come to the right source! Compression Molding to produce custom urethane parts has been one of Plan Tech’s many specialties for decades. Plan Tech designs and manufactures all of our own aluminum compression molds in our in-house machine shop designed for hot-cast urethane. Compression molding polyurethane allows us to mold polyurethane parts that would be impossible to mold with standard open cast urethane process, or would require time-consuming very costly machine shop work. We offer many types of high-quality compression molding options: Made In USA Urethane Compression Molding Specialists! Molded Polyurethane Wear Strips: Our compression-molded polyurethane wear strips are cast and molded with ultra-tough materials and have proven to cut downtime, maintenance time and cost of parts. In our business, quality is critical. We’ve built a three-decade reputation for reliability, precision, and service, and our dedicated team of engineers has made Plan Tech an industry leader in the production of molded polyurethane wear strips. Molded Urethane Balls: Solid urethane balls can be used for check valves, light load ball bearings, relief valves, etc. Manufactured in several durometers and offered in different colors, according to customer’s specification. Our proprietary urethane formula allows our solid […]

Cast Polyurethane Glossary of Terms

– A – Abraded: Worn away by friction. Abrasion: Wear due to friction. Abrasion Test: Determination of the rate of wearing away by friction. Abrasion Tester: A machine for determining relative abrasion resistance. Accelerated Aging: Intensive exposure to operating conditions to obtain an early change in physical properties of an elastomer. Accelerated Life Test: A method designed to approximate in a short time the deteriorating effects obtained under normal service conditions. Additive: A material which does not effect the chemical reaction but is included to alter the final product such as fillers, flame retardant, etc. Adhesion: Basically, the adhering, clinging, bonding or sticking of two material surfaces to one another, such as polyurethane to polyurethane, polyurethane to metal, polyurethane to rubber. Adhesion Failure: The separation of two adjoining surfaces due to service conditions. Adhesive: A material which, when applied, will cause two surfaces in contact with each other to bond together. Adhesive Coating: A coating applied to a surface to increase its bond to an adjoining surface. After cure: A continuation of the stabilization process after the cure has been carried to the desired degree for a predetermined length of time. Aging: To undergo changes in physical properties with age or […]

Urethane Wear Strips – Custom Molded Wear Strips!

Urethane wear strips provide sliding supports and guides; it also helps in curving and straightening tracks that are extruded or machined. Over the years the Plan Tech engineering team has produced urethane wear strips for a large number of industries, including packaging, bottling, chemistry, pharmaceutics, ceramics, glass, food processing, mechanics, paper, etc. Urethane’s unique features of impact resistance, tensile strength at high temperatures, and its ability to absorb energy under high-stress levels have made it the best in the industry. Our ultra-modern in-house machine shop is equipped with world-class materials and state of the art facilities which has given our engineering team access and an opportunity to produce the very best urethane wear strips the industry has to offer. Plan Tech’s standard urethane wear strips have been proven to meet the highest industry specifications for thickness and durometer, making them perfect for severe applications. Key features of Plant Tech’s urethane wear strips Self-lubricating Low coefficient of friction High wear resistance Good vibration and noise absorption High dielectric strength High chemical resistance, no corrosion No moisture absorption High impact and fracture strength Our urethane wear strips are currently one of the best used in supporting and […]

Keyed Polyurethane Shafted Rollers – Made In USA!

Keyed polyurethane shafted rollers are high precision urethane products that find use in a good number of industries today. They are designed and manufactured by us in our world-class in-house machine shop that is fully-equipped with sophisticated machinery and equipment. Like every one of our other urethane parts and products, we only make use of high-quality urethane materials for the production of our keyed polyurethane shafted rollers. Also, to make sure they are of top-grade quality and the very best in the market we always apply speed and precision which allow us to maintain consistency in quality. Our experience over the years has also given us the ability to meet the high-volume demand for Keyed Polyurethane Shafted Rollers from our various clients. Our keyed polyurethane shafted rollers boast superior physical property which is evident in their high resistance resist wear, abrasion, corrosion, chemicals, and environmental conditions. Our in-house precision engineering unit has the technical ability to cast keyed polyurethane shafted rollers in many different shapes, sizes and durometers that will meet the requirement of any application. So, no matter the type of application you require keyed polyurethane shafted rollers for, you can always count on Plan Tech to […]