Urethane Belt Scrapers are a critical cast urethane part that Plan Tech manufactures for any application. Many different profiles and shapes are available from OEM catalogs which Plan Tech can reproduce or make custom one off urethane belt scrapers to meet and exceed any required fitment. Urethane belt scrapers are typically located at the exit of a conveyor belt system mounted underneath the shoot. The urethane belt scrapers will be adjusted to just barely drag on the conveyor belt to knock loose any foreign objects like rocks and debris. Most urethane belt scrapers will be cast from a sheet and waterjet cut to any needed profiles or if more detail is involved Plan Tech’s in house mold making capabilities will accomplish any goal. Plan Tech’s team of engineers and sales grew will learn each and every application and is available to help recommend the correct material and hardness for any job. High abuse urethane belt scrapers are also very common and require a steel core to be molded inside the scraper. Any bolt location spacing or thru hole configuration is available. Plan Tech can also supply any color or hardness for many different urethane scrapers and conveyor material processing applications. […]

AGV Urethane Wheels – AGV Stacker Wheels

AGV urethane wheels also know as AGV stacker wheels are custom cast from high-quality material for any harsh environment or continuous operation. AGV urethane wheels can be up to 12” in diameters and are available in any hardness or color. Most common AGV urethane wheels are cast from an 80A hardness for maximum service life and good traction properties in any environment including freezers and warehouse floors. We can duplicate your existing urethane automated guided cart wheels or reinvent the wheel for your custom AVG urethane wheel needs. When we recoat your existing urethane automated guided cart wheels most cases it is less expensive than an original replacement. Urethane is more durable than many OEM materials such as rubber and plastic. With Plan Tech’s high tech bonding process our material is chemically bonded to the hub or AGV urethane wheels for high load and high-stress applications. Urethane functions well in standard temperatures ranging from 0°F to +170°F ideal for most applications. Our engineering department can calculate the speed and load of the application and also determine the correct size of the wheel and coating ensuring replacement parts will outperform expected the lifespan of tradition wheels. With a […]

Case Study: Manufacturing Urethane Sprockets

When it comes to manufacturing urethane sprockets, there is one aspect that is more important than anything else: abrasion resistance. That’s what we keep in mind when we develop and create urethane sprockets. We use tight tolerance urethane sprockets that really make a dramatic difference in the manufacturing process in terms of productivity and longevity. One of the keys to manufacturing these tight tolerance urethane sprockets is using anticipated shrink vs wall thickness and shape to produce tight tolerance technique when modeling the sprockets. What Are the Benefits of Tight Tolerance Urethane Sprockets? Prior to the new tight tolerance technique employed when creating urethane sprockets, many sprockets would break down easily due to the teeth wearing down. However, a new, innovative approach was taken where close tolerance is used in molding, followed by machines that are incredibly precise. That has resulted in tight tolerance urethane sprockets that are much more resistant to abrasion. Now, the new model of right tolerance urethane sprockets has been able to stand up to wear and tear in the field and is proven to be much more resistant to breaking down. If you’re looking for a sprocket that runs smooth and is going […]

Urethane Jack Pads – Automotive Urethane Jack Pads

Urethane Jack Pads are custom cast for the most demanding heavy load applications. Urethane jack pads are nonmarking and made from high-quality material that will outlast similar materials. The common hardness of 95A to 60D allows for the jack pad to retain traction from sliding out as it will take the shape of uneven surfaces locking the pad in place. Our customers that install urethane jack pads rely on Plan Tech’s 30 years of experience for high-quality bolt on Trestle Jack Urethane Pads for heavy equipment lifting loads upwards of 30 tons! Plan Tech also specializes in OEM automobile manufacturer urethane jack pads for insert or keyways on lifting locations for vehicles. These custom molded urethane adapter jack pads are supplied in the spare jack kit in many foreign and domestic automobiles to protect the car’s undercarriage from jack damage. Urethane jack pads have an extremely long service life and will outlast many automobiles. Replacement or OEM aftermarket replications are easily reverse engineered by a team of product development engineers at Plan Tech to ensure proper fitment and functionality. Replacement parts can be reproduced from a simple sketch or sample part. Frequently we go from concept design to finished […]

Custom Urethane Tubing – Cast Urethane Tubing

Custom urethane tubing for machining stock is available in any hardness for the most demanding applications. Using high-quality polyurethane prepolymers from world leading chemical suppliers Plan Tech is able to produce high-performance custom urethane tubing for any application. Plan Tech’s in-house mold system has countless OD and ID configurations in 12’’ sections. We find most of our customers will use our custom urethane tubing to be machined into hundreds sometimes thousands of parts. 95A durometer hardness will turn quickly for many different washer and spacers combinations. Soft durometers need to be ground and at Plan Tech we have a urethane machine shop with dedicated machines designed for theses jobs with tolerances as tight as +/-.005. Plan Tech can supply any size urethane tubing with tolerances as tight as +/-.010 in any hardness. Custom urethane tubing is also chemical resistance to most commercially used chemicals and has a recommended temperature range from -20 to 170F. At Plan Tech we can produce custom urethane tubing with a turned or ground finish for any hardness coating. Custom urethane tubing can be designed to be flexible in one area with dampening or sealing characteristics and also rigid in other areas […]

Urethane Tube Stock – Polyurethane Tube Stock

Urethane tube stock from cast high-quality machinable polyurethane material suited to fit any applications is available at Plan Tech. We supply urethane tube stock up to 48 inches tall and available in most common nominal OD & ID sizes with a tolerance of +/-.030. Each urethane tube is hand cast allowing us to tailor our urethane material to add lubricity or an anti-static urethane for rolling applications. Custom urethane tubes are available on request in durometers from 20A to 70D. All standard colors are stock in-house including OSHA approved safety orange. Urethane tube stock reduces OEM product due to easily being made into thousands of different parts, from sealing gaskets to special urethane washers for electric motors. Urethane tube stock has superior cut and abrasion resistance with the ability to self-heal in can be formulated for high or low rebound. Urethane performs excellent in outdoor applications with UV protection against aging. Urethane tube stock is lightweight and has outstanding low-temperature properties making urethane a clear choice other similar material. At Plan Tech we have an Armorglide additive that has similar properties to UHMW, A huge benefit is that urethane tube stock can be cast to almost any OD […]

Tips On How to Specify Urethane Idler Rollers

Polyurethane is a popular choice when searching for urethane idler rollers. That’s because urethane coated idler rollers have some very dynamic properties, are resistant to wear and an excellent ability to withstand friction. Not to mention the fact that urethane idler rollers are able to operate optimally in a variety of conditions – from cold and freezing temperatures to hot and humid. Before you make your decision, it’s important to understand the difference of materials when it comes to idler rollers. Urethane coated idler rollers should be on the top list of your consideration for the following reasons: 1. Urethane Idler Rollers are Great for a Variety of Torque Levels and Loads Assessing the amount of weight that will be applied and the level of torque to urethane idler wheels is critical to ensuring that the urethane idler wheel stands up to wear and tear and lasts for many years to come. Fortunately, it’s relatively easy to calculate. Once you have the anticipated torque level and load weight, leave the rest to us. We will come up with an excellent urethane idler rollers that is customized in size to meet the demands of your intended use. 2. Superior […]

Urethane Sheaves Pulleys – Wear Resistant!

Urethane sheaves pulleys are frequently used to protect steel cables for lifting applications. Urethane has a great ability to absorb vibration for a smooth and quiet operation. Urethane sheaves pulleys are commonly found in elevators and amusement park rides. Plan Tech specializes in custom urethane sheaves and pulleys for any environment. Urethane will have an extended service vs. similar material even underwater and outside conditions are no problem for Plan Techs high-performance material. Any wire or cable size cable can be machine profiled into urethane sheaves and pulleys making replacement parts easy. Most Urethane sheaves and pulleys will have a steel core or can be completely cast from urethane for low-cost replacement parts. From prototype pieces to high volume Plan Tech will design tooling around production needs and can incorporate any company logo or part numbers may also be molded into urethane sheaves pulleys. Urethane is also chemical resistance to most commercially used chemicals and has a recommended temperature range from -20 to 170F. At Plan Tech we can produce Urethane sheaves and pulleys up to 12’’ Diameter with a turned or ground finish for any hardness coating. Solid cast Urethane sheaves and pulleys can be up to 48’’ […]

Polyurethane Pulley Steel Core – Polyurethane Pulleys

Polyurethane pulley steel core are custom cast to produce pulleys for any industry requiring a high-performance material with a long service life. Since polyurethane is FDA compliant – polyurethane pulleys with a steel core can be easily reproduced for low-cost replacements and can be cleaned using most chemicals. From small to large cast polyurethane pulleys Plan Tech can produce most polyurethane pulley steel core applications in 4 weeks or less. Being a custom cast polyurethane product we can allow our customer to purchase any color or hardness required for the applications. Our team of engineers is also ready to help design new polyurethane pulley steel core from a simple sketch or drawing. The steel core of the pulley will be de-greased and media blasted before bonding the polyurethane directly to the core. This chemical bond ensures the pulley will have a long service life. Frequently we hear that our polyurethane coatings outlast the original equipment. Finished polyurethane pulley steel core and machine turned on a lathe to ensure a balance wheel for high-speed applications. Polyurethane is also chemical resistant to most commercially used chemicals and has a recommended temperature range from -20 to 170F. At Plan Tech we […]

How to Manufacture Custom Urethane Parts?

Custom urethane parts have revolutionized our modern industrial world. That’s because custom urethane parts are cheaper than ever to produce using 3D printing technology, while also remaining incredibly durable and long lasting. Part of that process is creating a realistic model online of what the finished product will look like. If you’re figuring out the important aspects of creating custom urethane parts, you’ll want to be especially careful when considering the following aspects: 1. Designing Accessible Urethane Parts This may seem glaringly obvious, but it’s important that you think of the actual use of your custom urethane parts in practice. As an example, blind internal corners may not be a viable option, or if they are they may take a while longer to produce and be more expensive. Consider the urethane casting techniques that are carried out when designing your custom urethane parts. 2. Adjust for the Potential Shrinkage of Custom Urethane Parts Urethane parts are known to stay relatively sturdy and free of signs of wear for many years to come of heavy use, however, they do tend to shrink a bit. As a general rule of thumb, you can expect about 0.15% of shrinkage to occur, […]

Custom Molded Urethane Dunnage – Polyurethane Dunnage

Custom Molded Urethane Dunnage parts have been manufactured at Plan Tech for over 30years! Plan Tech will calculate and recommend the correct mechanical properties to protect the most delicate components to large construction equipment. From prototype to high volume our sales team of engineers will work on every detail for truly custom molded urethane dunnage parts for any profile on any application. Custom Molded Urethane Dunnage Many factors are involved in designing custom molded urethane dunnage parts with cost being most important. We also provide replacement existing custom molded urethane dunnage parts that will provide maximum performance for any shipping needs. Our urethane dunnage parts and will meet or exceed OEM specifications offering increased wear resistance over traditional rubber products, making urethane an ideal choice for shipping delicate parts. Custom Molded Urethane Dunnage Parts In addition to manufacturing new polyurethane parts, we also offer recoating services. Existing dunnage parts with a metal core that is still in good shape can be re-coated, cleaned and refurbished with a new polyurethane coating extending the life of the custom molded urethane dunnage parts. New and recovered cores can be manufactured to withstand a variety of load weights at variable […]

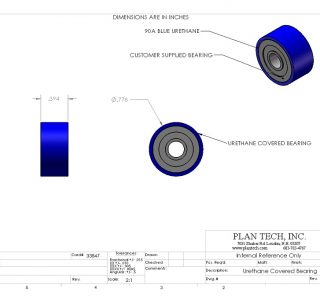

Advantages of Urethane Bearings vs Rubber

Business and industry try to improve productivity and reduce safety claims as much as possible, so it’s no surprise that businesses want to use the most cost-effective option when it comes to bearings. Many fall into the trap of thinking rubber bearings are better than urethane bearings, but that’s simply untrue. While there are advantages to both, urethane often outperforms rubber in most cases and provides the largest return on investment with the durability and longevity, not to mention the efficiency, that urethane bearings offer. If you’re deciding between rubber bearings and urethane bearings, here are a few examples that demonstrate why urethane bearings are the superior choice. Urethane Has Superior Tensile, Abrasion Resistance, and Tear Strength This is one area where engineers, purchasing managers, and manufacturers often regret specifying any material other than urethane. Save yourself the difficulty of materials breaking down on you in the future and opt for urethane bearings. While rubber (along with silicone and nylon) often decomposes from wear and tear, urethane stays in solid condition for years to come. You’ll be thankful you decided to select urethane covered bearings due to the fact they have the longest manufacturing life to it and can stand […]

Kimpex Urethane Track Sprockets Reproduced

Kimpex urethane track sprockets are used in many industries requiring high-performance urethane sprockets and parts. From Snowmobiles to Agriculture Equipment Plan Tech manufactures reproduction kimpex urethane track sprockets for customers worldwide. We are a leading urethane sprocket manufacturer in the United States and have been producing custom molded urethane parts for over 30 years! Reproduced Kimpex Urethane Track Sprockets Frequently we are approached with a custom kimpex urethane track sprockets reproduction requiring additional additives into the urethane formula and or hardness alterations to adapt for chain mismatch. Plan Tech supplies thousands of discounted reproduction kimpex urethane track sprockets sizes for custom applications around the world every year. Most reproduced kimpex track sprockets are produced using compression molding. Our state of the art machine shop has superior mold designing and production capabilities. We will produce a mold with a mirror image on each half of the mold splitting the reproduction kimpex urethane track sprockets in the middle. Reproduction Kimpex Urethane Track Sprockets Each half of the mold will be poured and closed before the polyurethane material is cured then placed in one of many 50 ton heated presses we have until the replacement kimpex urethane track sprockets are […]

Tight Tolerance Urethane Wheels Manufacturing Process

When it comes to the manufacturing process of urethane wheels, we focus on the best quality and custom precision to our customer’s specifications. That’s how we are able to create some of the best industrial products in the industry and are a leading provider of urethane wheels. Additionally, we take great pride in the ability to create urethane wheels in all shapes, sizes and a variety of durometers. Our polyurethane wheels have gained us a reputation of quality, durability, and longevity, but how do we do this? How are we able to manufacture top of the line urethane wheels? Our Urethane Wheels Are About Your Needs When we design and manufacture our urethane wheels, we always have the end result and client’s needs at the forefront of our mind. If you need a specific tolerance, diameter or firmness, we have it covered. No matter your application or desired outcome when it comes to urethane wheels, we can turn that idea into reality. This flexibility allows you to select a wheel specifically geared for your project. No more trying to “make due” with what’s available. Now, you can create a custom end product that is that much more smooth, clean and of […]

Polyurethane Pads – Custom Polyurethane Pads

Polyurethane Pads ? You’ve come to the right source! Polyurethane Pads have been manufactured at Plan Tech for 30 years! We have a custom polyurethane pads manufacturing line dedicated to producing new and replacement custom urethane pads. Our pads are made from high\low rebound prepolymers available in any color and hardness. Custom shapes and sizes of polyurethane pads can easily be reproduced from a sample part or sketch. Our team of design engineers can build custom polyurethane pads profiles for the most demanding applications. Most polyurethane pads are water jet cut from urethane sheets – providing a low-cost solution for custom polyurethane pads. Waterjet cut polyurethane pads services at Plan Tech manufacture high volume profiled polyurethane pads – frequently it takes less than a week for us to manufacture thousands of polyurethane pads replacements. Just a few examples of the custom polyurethane pads that we manufacture include: Polyurethane Pads Urethane Impact Pads: Urethane impact pads are found in almost every application requiring abrasion resistance and excellent load-bearing performance. Our custom urethane impact pads will even hold up to the harsh environment of being media blasted to provide traction for parts being processed. Typically urethane impact pads are made from […]

Snowcat Urethane Drive Sprockets – Snowcat Drive Sprockets

Snowcat Urethane Drive Sprockets are custom cast for critical design specifications and will meet the highest quality standards. Plan Tech offers snowcat drive sprockets with up to 60% greater strength vs similar material for industries that require high-performance snowcat urethane drive sprockets. Our snowcat urethane drive sprockets provide a long service life and reliable performance that are precision cast from high-quality polyurethane material supplied by world leaders. Snowcat Urethane Drive Sprockets For 30 years Plan Tech has mastered molding snowcat drive sprockets for the most demanding applications and extreme weather. Snowcat Urethane Drive Sprockets perform very well is cold climates without getting brittle like similar material. Due to urethanes great ability to absorb an impact and return to its original shape will result in a smooth quiet operation for years and adapt for any mismatch. Plan tech can incorporate any keyway needed or add a steel core for high strength industrial urethane sprocket designs. Existing steel snowcat urethane drive sprockets may be stripped and recoated when the hub or core is in good shape can be re-coated, cleaned and refurbished with a new urethane coating extending the life of the wheel. New and recovered snowcat urethane drive sprockets […]

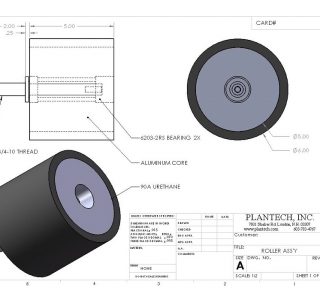

Urethane Rollers – Top Advantages and Performance

Urethane Rollers have a variety of uses in many industrial applications. If you’re in the construction business, then you likely understand the importance of a high-quality, long-lasting roller. Many opt for rubber or other material rollers as they can sometimes be a less expensive upfront cost (which isn’t always true – urethane rollers can be incredibly economical as well!) but end up paying a higher price later on down the road. If you’re looking into the types of rollers that should be used for your manufacturing or construction business, urethane rollers should be on the top of that list no matter what your intended application is. Urethane Rollers Are Weatherproof One thing you’ll notice right away is that urethane rollers are so versatile and able to withstand both extremely hot and extremely cold temperatures. This differs greatly from rubber wheels, which easily wear when exposed to extreme heat and extreme cold. This is because urethane is much more stable and dense compared to rubber. If you work in the heat of the desert or the cold New England winters then this is extremely important for you. In comparison to rubber rollers, Plan Tech’s rollers are much more heat and cold […]

Urethane Gear Sprockets – Custom Gear Sprockets

Urethane Gear Sprockets are designed to operate quietly for high demand applications. Urethane has a great ability to absorb an impact resulting in smooth operation and extended run time vs similar materials. Polyurethane resins have superior physical properties making urethane gear sprockets a go-to choice when choosing a high-performance material. Urethane gear sprockets can easily be molded to size resulting in low-cost high volume applications that often times have little tooling start-up cost on new urethane gear sprockets. Plan Tech’s team of engineers can reverse engineer an exciting gear sprocket or design a completely new one with any profile or detail added. We have specialized in reproducing discounted urethane gear sprockets for many different industries. Our largest customer had been using 2500 sprockets annually and was having issues with an aftermarket injected urethane company. After testing we found our sprockets to be 20% stronger vs the OEM equipment that was being discounted and over 60% stronger than the injected urethane! We also found the cut and tear strength was drastically increased using our 50D material. We frequently have customers come to Plan Tech for a custom application not offered by OEM replacement parts to alter how a […]

Urethane Molded Parts – Custom Urethane Molded Parts

Urethane Molded Parts ? You’ve come to the right source! Urethane Molded Parts begin with an AutoCAD urethane mold design from our in-house mold engineers. To manufacture urethane molded parts we have a variety of molding design operations using rotational force and compression molding. Most common molds are called open cast molds and are typically produced from aluminum that consists of many parts and pieces to make the finished mold to produce tight tolerance urethane molded parts. Sometimes if the mold cannot be machined and we will make an oversized part from metal to use as a master pattern by casting around the master pattern to produce a urethane mold so we can cast urethane molded parts. We utilize the best in class polyurethane from world’s leading polyurethane manufacturers and manufacture the industries largest selection of high-quality Urethane Molded Parts some of which include: Urethane Molded Parts Urethane Mounting Blocks: Urethane mounting blocks are non-marking and will absorb noise and help reduce harsh slamming from equipment. Being able to cast urethane mounting blocks to size allows Plan Tech to supply high-quality mounting blocks with any profile or detail needed for any custom urethane molded parts application. Urethane Stop Cushions: […]

Frequently Asked Questions – FAQs

What is the difference between Ester & Ether Urethane? Our primary choice of prepolymer material is Ether-based due to its superior physical properties above 90A hardness and that it does very well in wet or cold conditions. Ester urethane based products do very well against abrasion resistance and handle heat and chemicals better than ether’s but do very poorly against moist humid conditions. At Plan Tech we stock all durometers of each base polyurethane material. What is the difference between injection urethane vs hot-cast urethane? Hot cast urethane products are often handmade and an easy way to reproduce medium to high volume parts with physical properties superior to injection molding for a lot less in up-front tooling cost. Do you have high rebound urethane? Yes, we carry low and high rebound urethane for any applications in any hardness or color. How does spin casting work? By using rotational force we are able to produce parts complete with no secondary operations. Our biggest demand for spin casting is for precision urethane sheets with tight tolerances. What are your compression molding abilities? Sprockets, gaskets and bushings can all be easily reproduced via compression molding with parts up to […]