Urethane drive belts are produced at Plan Tech by the use of what we like to call our family mold system. This system of molds can easily adapt to any tight tolerances that are required and mold urethane drive belts in high volume.

By casting a longer tube Plan Tech is able to machine any needed profile into the drive belts and grind the OD with custom build CNC lathes. We also have to build a custom indexing machine capable of machine cutting urethane drive belts in a high volume of any durometer hardness. Urethane drive belts are used in many different industrial applications. We have found our largest customers for polyurethane drive belts are in the assembly and manufacturing settings.

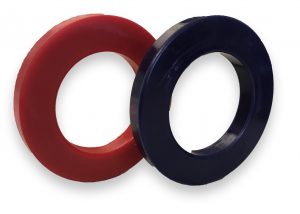

We frequently hear how our drive belts easily outperform rubber and are easily available in almost any size. Plan Tech also offers reverse engineering of urethane drive belts of all sizes. Larger size urethane drive belts will be molded to size from tooling designed and produced in-house. Often times Plan Tech can prototype urethane drive belts and turn to high volume in just a few weeks! FDA approved formulas are also available with a variety of additives to enhance the physical properties of our urethanes performance.

Machining cast urethane parts require specialized equipment and training. Here at Plan Tech we utilize #D CAD Design Software Solidworks and make all of our own molds in-house for speed, accuracy and precision. We control the entire process from design to manufacture. Custom Mold making is at the very core of what we do. Our machine shop includes CNC Lathes, Mills and Grinders for machining cast urethane parts. We also have manual mills as well as a sheet metal and welding area. In addition, we have a Flow Water jet with 48×96 inch sheet capabilities and can cut a list of materials like Polyurethane, Steel, Stainless Steel, Aluminum, Carbon fiber, and most plastics.

Please Contact us for further details regarding drive belts!